New - Northfield Uni-Point

Contact us for pricing

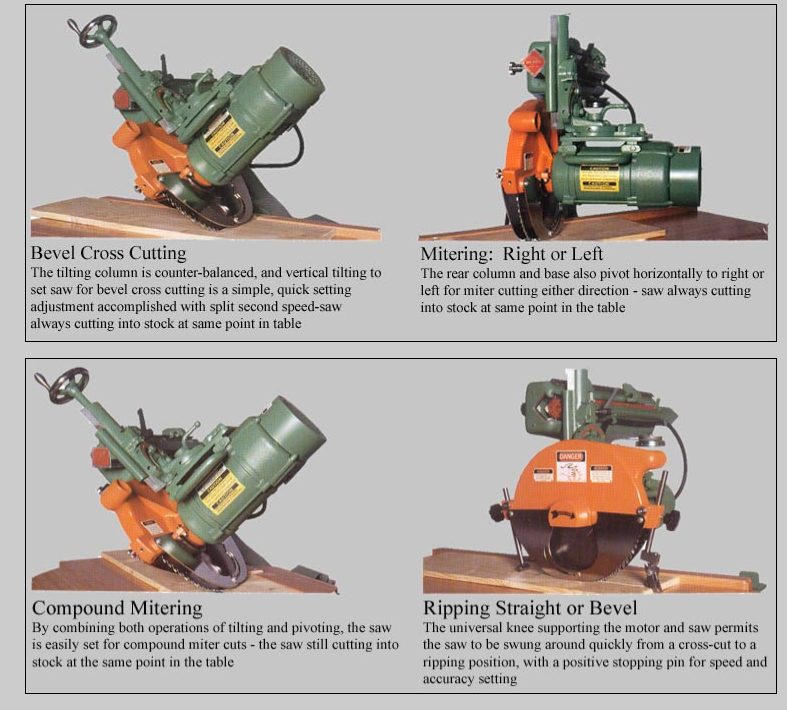

The Northfield Uni-Point Radial Saw provides an amazingly fast and entirely new wood cutting principle called "ONE POINT CUTTING." This means that the saw blades always enters the stock at the same point in the table regardless of how it is set for a vertical, horizontal, or compound miter cross cut angle.

Cuts everything including TIME and COSTS!

Specifications Model X36A

**Now Available: Single Phase Arbor Motors

These motors are available for new machines and retrofitting applications. 5 HP 1 phase motors pull 22 full load Amps. Standard Equipment: Regular machine complete with guard and kick back preventer, magnetic starter with 110 volt at pushbutton and automatic electric brake.

Extras

NEMA 12 Electrics with Disconnect, 24 Volt at Pushbutton, Rolling Tables, Graduated Gauges with Stops, Dado Extensions, Dado Gaurds, & Lube Systems. For extras not listed, please contact us.

Cuts everything including TIME and COSTS!

Specifications Model X36A

**Now Available: Single Phase Arbor Motors

These motors are available for new machines and retrofitting applications. 5 HP 1 phase motors pull 22 full load Amps. Standard Equipment: Regular machine complete with guard and kick back preventer, magnetic starter with 110 volt at pushbutton and automatic electric brake.

Extras

NEMA 12 Electrics with Disconnect, 24 Volt at Pushbutton, Rolling Tables, Graduated Gauges with Stops, Dado Extensions, Dado Gaurds, & Lube Systems. For extras not listed, please contact us.

1. One Point Cutting

"One Point Cutting" not only reduces angular cross cutting operations to an unusual degree of mechanical simplicity, but eliminates some adjustment motions entirely. It cuts down the time factor on other adjustment motions, is more adaptable to short cut production methods, and in many other ways greatly increases total production per hour.

2. Blade Height Under Constant Control

It is never necessary to raise or lower the saw blade for any angle of cross cut. Once properly set, it is always correctly positioned, even on miter cuts. Such adjustments eliminated entirely. Time saved!

3. Heavy Cast Iron Construction

Massive iron components, accurately machined, insure lasting alignment and close tolerance cutting. The vibration dampening effect of cast iron adds years to the lifetime of the machine, while providing the smoothness of operation and accuracy that you require for your most intricate work.

4. Gauges Always Remain Fixed

Because the saw blades enters the cut at the same point, it is never necessary to rearrange the material to be cut or change the stops or gauges when changing cross cut angles. "One point cutting" eliminates the necessity of adjusting work and gauges when the saw blade cuts at different points according to degree of an angle. More time saved!

5. Wearing Parts of Hardened Steel

All vital moving parts are protected by hardened steel. The telescoping ram is special heat treated hardened steel. The housing is provided with hardened steel bearing ways. The 32 roller bearings are hardened steel to assure easy finger touch motion and absolute permanent accuracy. Breakdowns or time out for replacing parts is eliminated because Uni-Point is built to last a lifetime.

6. Permanent Guide Fence

Again, "one point cutting" allows the saw blade to pass through the guide fence at the same point. Cutting through the fence at different points, according to angle, mutilates the fence requiring constant replacements. Thus, with Uni-Point the fence lasts for years.

7. One Stop-and-Gauge Adjustment per job

Not only can the stops remain fixed when angle of cut is changed, but can remain fixed however many changes are made, provided the length of the material is the same. In other words, gauges need only be changed when the entire job is changed.

8. Work Always in Full View

With a telescoping ram, the entire upper assembly recedes at the completion of each cutting stroke, leaving table free and clear for measuring and other work. No long arm to work around.

9. All Locking Levers are Easy Accessible

All adjustments are made in front of the machine, above or below the table. No reaching over the table. Everything handy and simple to adjust.

10. Stops Automatically Lock Uni-Point at All Common Angles

Instantaneous locking action provided at all common positions, such as straight cross-cutting, 45 degree bevel, 45 degree miter right or left, 45 degree compound miter and ripping.

"One Point Cutting" not only reduces angular cross cutting operations to an unusual degree of mechanical simplicity, but eliminates some adjustment motions entirely. It cuts down the time factor on other adjustment motions, is more adaptable to short cut production methods, and in many other ways greatly increases total production per hour.

2. Blade Height Under Constant Control

It is never necessary to raise or lower the saw blade for any angle of cross cut. Once properly set, it is always correctly positioned, even on miter cuts. Such adjustments eliminated entirely. Time saved!

3. Heavy Cast Iron Construction

Massive iron components, accurately machined, insure lasting alignment and close tolerance cutting. The vibration dampening effect of cast iron adds years to the lifetime of the machine, while providing the smoothness of operation and accuracy that you require for your most intricate work.

4. Gauges Always Remain Fixed

Because the saw blades enters the cut at the same point, it is never necessary to rearrange the material to be cut or change the stops or gauges when changing cross cut angles. "One point cutting" eliminates the necessity of adjusting work and gauges when the saw blade cuts at different points according to degree of an angle. More time saved!

5. Wearing Parts of Hardened Steel

All vital moving parts are protected by hardened steel. The telescoping ram is special heat treated hardened steel. The housing is provided with hardened steel bearing ways. The 32 roller bearings are hardened steel to assure easy finger touch motion and absolute permanent accuracy. Breakdowns or time out for replacing parts is eliminated because Uni-Point is built to last a lifetime.

6. Permanent Guide Fence

Again, "one point cutting" allows the saw blade to pass through the guide fence at the same point. Cutting through the fence at different points, according to angle, mutilates the fence requiring constant replacements. Thus, with Uni-Point the fence lasts for years.

7. One Stop-and-Gauge Adjustment per job

Not only can the stops remain fixed when angle of cut is changed, but can remain fixed however many changes are made, provided the length of the material is the same. In other words, gauges need only be changed when the entire job is changed.

8. Work Always in Full View

With a telescoping ram, the entire upper assembly recedes at the completion of each cutting stroke, leaving table free and clear for measuring and other work. No long arm to work around.

9. All Locking Levers are Easy Accessible

All adjustments are made in front of the machine, above or below the table. No reaching over the table. Everything handy and simple to adjust.

10. Stops Automatically Lock Uni-Point at All Common Angles

Instantaneous locking action provided at all common positions, such as straight cross-cutting, 45 degree bevel, 45 degree miter right or left, 45 degree compound miter and ripping.